Remember the Suez Canal fiasco?

It was a little bit human error, a little bit poor planning, and it caused a really big supply chain disaster. In fact, it left 12% of global trade stuck in limbo because of a jammed ship in the Suez Canal.

That’s a procurement risk. A particularly costly one.

It ended up costing the world about $9 billion per day, in fact.

While most procurement risks aren’t as high stakes, the Suez Canal blunder highlighted exactly how vulnerable the procurement process can be.

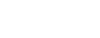

And there are several other types of procurement process risks besides supply chain disruptions, including:

- Contractual

- Financial

- Political

- Reputational

Let’s dive straight into some procurement risks you should be conscious of and exactly how you can avoid them.

TL;DR

- Procurement risks can come in all shapes and sizes.

- An effective risk management strategy identifies potential risks and outlines how you can avoid them.

- Contract management software can help mitigate some risks in the procurement process.

1. Human Error

It’s no secret that procurement processes are extremely complicated and require lots of manual oversight. And anything that involves manual tasks is prone to human error.

Common errors that occur during a manual procurement process include:

- Typing in incorrect product codes

- Misfiling a contract

- Misplacing or scattering contracts

- Allowing access to specific people

As much as 10% of all contracts are lost in the wind. Who's to say how much of that is due to human error? We're willing to bet that it's quite a bit.

The solution: Have a rigorous procedure in place to double-check the data and paperwork. That way, you minimize the chances of making a mistake when entering information into your systems.

Even better, have a digital system with advanced search features like optical character recognition (OCR), so even if something does get misplaced, you’ll still be able to track it down.

2. Poor Vendor Management

You may have a couple of reliable vendors who are always available to provide products or services when needed.

But as your business grows, it’s harder to keep track of every single vendor to ensure nothing slips through the cracks. Now, the team managing vendors or implementation likely isn’t the same team who negotiated and signed the contract.

Suddenly, it feels like you only have part of the puzzle. You may not know what to look for when auditing vendors for purchases, approvals, payments, and more.

Poor vendor management is a significant risk for any business. It can lead to:

- Unforeseen expenses

- Missed opportunities

- Contract renewals you would have rather let lapse

The solution: Instead of poring over every piece of paperwork landing on your desk, use software to create an audit process for vendors. You can generate performance reports and review them frequently to identify issues.

As much as 85% of companies don’t use an analytics system to track risk — make sure you’re not one of ‘em.

3. Unreliable Suppliers

Here’s a maybe-shocking, maybe-not-shocking statistic for you:

A quarter of business executives admit that they’re not vetting their suppliers properly. And nearly half of those blame manual processes for the shortfall. That’s not great.

If you’re not vetting your suppliers, you’re setting yourself up for disappointment. It could mean you’re hiring a vendor who’s just not very good at what they do.

Similar to poor vendor management, unreliable suppliers can also present some serious risks.

Unreliable suppliers could mean:

- Slow delivery times

- Inconsistent quality control processes

- Sudden changes in pricing

And all of this impacts your bottom line.

The solution: Before onboarding a vendor, it’s important to do your due diligence and make sure they are reliable, trustworthy, and have the ability to provide what they offer.

Take time and resources to vet each supplier to ensure they can meet your standards before locking in a vendor contract.

Additionally, it’s important to have a contingency plan so you can quickly switch to another supplier if needed.

4. Contract Noncompliance

Remaining compliant with contracts can be tricky, especially if you’ve locked your business into terms that aren’t particularly favorable. But unlike one particularly creative Verizon customer, your business can’t fake its own death to get out of it. You’ve gotta comply.

Noncompliance carries serious consequences, like:

- Financial fallouts

- Legal disputes

- Run-ins with regulators

Contract noncompliance can happen for a variety of reasons, like a change in circumstances or a misunderstanding of the contract terms. It’s not always malicious, but should always be taken seriously.

The solution: The best way to reduce the risks associated with contract noncompliance is to ensure that all contracts are accurately written and closely followed using contract management software.

If manual compliance tracking is your cup of tea, more power to you. But for those who prefer coffee, contract management software is a welcome sigh of relief. Here are just a few ways it can help ensure compliance:

- Sets up automated notifications for key events

- Gives the right people access to the right contracts

- Simplifies regular audits

- Minimizes mistakes caused by manual data entry

Both parties should be familiar with the terms of a contract before signing, and any changes should be documented in writing. If a breach does occur, it’s important to act fast to minimize potential damage.

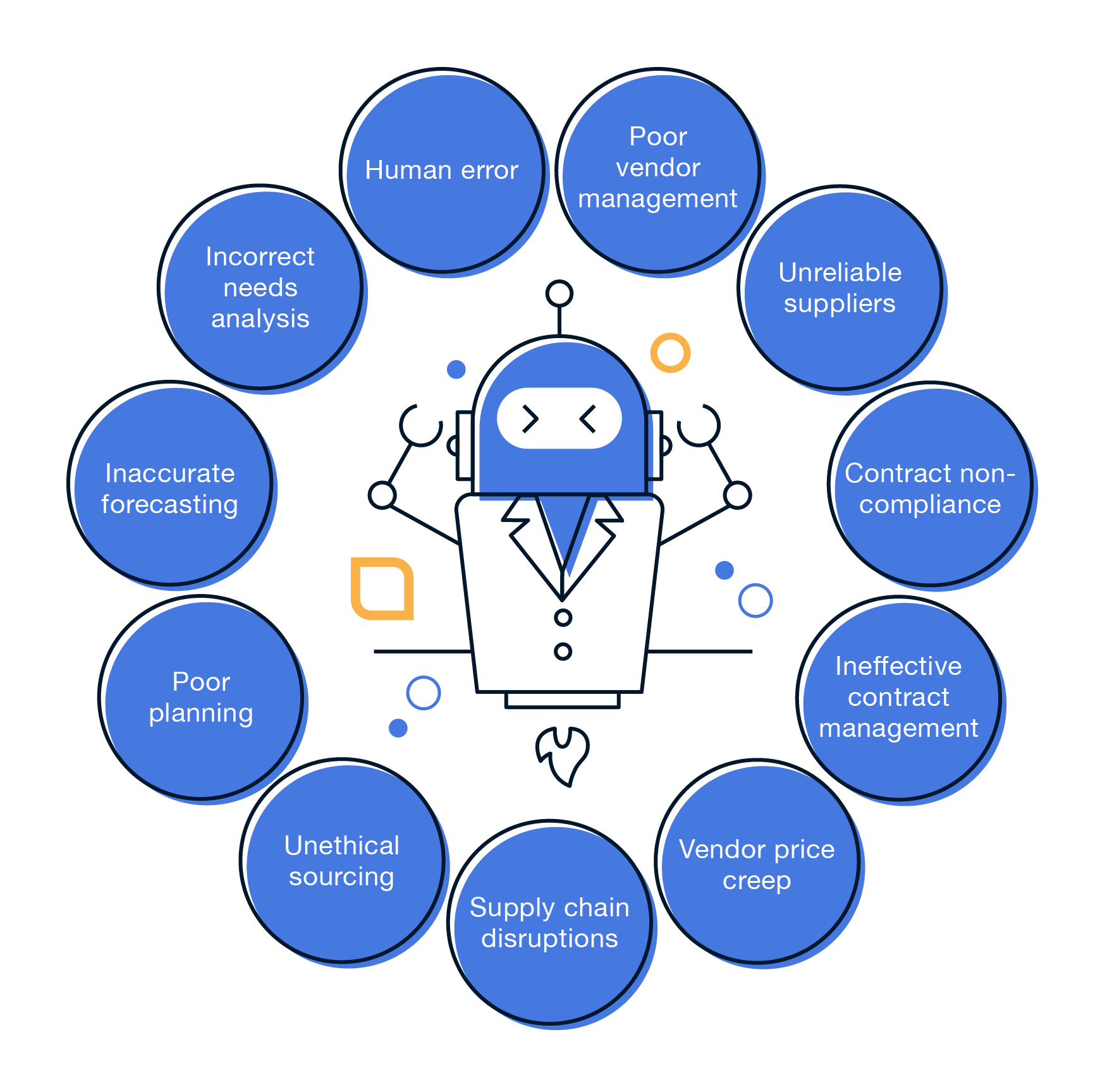

5. Ineffective Contract Management

It’s no easy feat to juggle thousands of contracts at any given time. And if you can do it efficiently and effectively without the help of software, well, we envy you!For the average person, it’s not exactly a walk in the park.There are a lot of things that can go wrong in the lifecycle of a contract, including:

- Lost contracts

- Missed obligation dates

- Working from the wrong documents

And each of these results in lost profits.

The solution: Proper contract lifecycle management is key to ensuring that procurement contracts are being handled effectively. Organizations should have a clear understanding of what their current processes look like, as well as how they can be improved.

But procurement managers are busy. And finding (and implementing) a good contract management solution often takes time.

Effective contract management software should be easy to implement and even easier to use. Why have all the bells and whistles slow you down when what you need is a simple solution that works for you — fast?

6. Vendor Price Creep

We’ve all been there. One second you’re on budget and ready to take on the world, and the next you’re swimming in unexpected fees, scrambling to see what went wrong.

Price creep can occur for many reasons. And it's not always outlined in your previous year's contract. Here are a few causes of unexpected price hikes:

- Inflation

- Rising shipping costs

- Increasing producer prices

- General expense increases

Price hikes can slip through the cracks easier than you might think. And it's even more probable if your team lacks visibility into the process or is missing key information when a contract comes up for renewal.

The solution: Stay apprised of similar industry pricing and macroeconomic trends so you can compare and verify if you're being quoted fairly. Use contract management software to make sure your vendor contracts are up to date, send notifications ahead of renewal dates, and list out any potential costs that may appear.

Additionally, you should take the steps necessary to ensure that all your teams are aligned and have access to the right data before contract renewals.

7. Supply Chain Disruptions

The past few years have shown exactly how delicate the global supply chain can be. Disruptions can occur for any number of reasons, including:

- Political instability

- Natural disaster

- Factory closures

- Cyberattacks

- Price fluctuations

- And yes, even human error

The Suez Canal mishap was serious, but nothing compared to the impact of the COVID-19 pandemic or the Russian invasion of Ukraine. Both have fueled energy crises, food shortages, and shipping delays across the globe.

Supply chain disruptions are one of the top risks facing businesses today, and as the world becomes increasingly globalized, they’ll be tough to avoid.

The solution: Proactive risk management is key when it comes to mitigating potential problems before they arise. While you can't prevent a pandemic, you can anticipate and plan for supply chain disruptions in your procurement process.

Here are three steps you can take to minimize the impact of supply chain disruptions:

- Diversify your suppliers: Having multiple suppliers at your disposal will ensure that you’re never left without a crucial component to complete your product.

- Build up extra inventory: If you’re able to, having a stockpile of materials can be helpful in times of crisis.

- Create a contingency plan: Having a backup plan will help you prepare if something goes wrong, as well as determine which suppliers should take priority and where resources should be allocated.

8. Unethical Sourcing

ESG has become somewhat of a buzzword in recent years.

It stands for: Environmental, Social, and Governance

It’s becoming a top priority for investors, which means it’s becoming a top priority for businesses and their suppliers.

Unethical sourcing is part of this new market trend.

Companies are increasingly scrutinizing their suppliers’ practices, like avoiding sourcing from countries or entities with:

- Human rights abuses

- Poor environmental track records

- Unsavory political practices

Noncompliance with ESG guidelines can be a big hit to a company’s reputation. This is why as much as 63% of B2B buyers say improving sustainability in their supply chains is a top priority.

The solution: Organizations should be proactive in understanding the ESG risks associated with their suppliers and put measures in place to reduce the risk.

This could include conducting due diligence on potential business partners, creating a code of conduct that all suppliers must sign, or implementing detailed supplier management policies.

By taking preventive action now and staying informed about current trends and regulations, companies can protect themselves from costly procurement risks down the road.

9. Poor Planning

Poor planning is a common procurement risk, and it can be a headache for everyone who is impacted.

It's frustrating for employees and it can lead to missed opportunities, decreased efficiency, and unexpected costs. Even worse, it could hurt your reputation with your customers.It’s kind of like McDonalds’ notorious ice cream machines. Ice cream is on the menu. But have you ever tried ordering one only to be told the machine is broken? It happens so frequently that it’s become a meme.

By not planning ahead to predict when machines will break so they can be fixed quickly, McDonald’s franchise owners have missed an unfathomable amount of potential sales.

Even worse, it’s become expected that the machines are broken, which means customers aren’t ordering ice cream even when the machines are working properly.

The solution: Under-promise, over-deliver.

Identify your goals and err on the side of caution when you put together a plan. Be realistic about what can be accomplished and have a backup plan if things don't work out.

When you've got a plan in place, make sure you're tracking its effectiveness.

Are deadlines being met? Are you staying within your budget? Are your employees happy and healthy?

If the answer is no to any of these questions, take your plan back to the drawing board. Good reporting, accountability, and transparency can go a long way in making sure your plans succeed.

10. Inaccurate Forecasting

Inaccurate forecasting is kind of like poor planning but a bit more financially focused.

Accurate forecasting is essential to successful procurement because it helps you accurately predict the costs associated with each step of the procurement process.

Without proper forecasting, there's no guarantee that you're getting the best price for your goods and services.

The first step to mitigating this risk is understanding what causes inaccurate forecasting in the first place.

Some common causes of inaccurate forecasting include:

- Not taking into account changes in customer behavior

- Not considering new product launches or discontinuations

- Not factoring in changes in seasonality

- Outdated data or methodology

- Not being able to get reports when needed

The solution: Considering data is everything when you’re trying to do the impossible and predict the future, detailed (automated) reporting can help.

Compliance, performance, and status reports can be used to identify the factors that have the greatest impact on sales, so you can make informed decisions about how to adjust your procurement strategies accordingly.

A few other steps you can take to improve your future forecasts include:

- Monitor your customers’ purchasing behavior

- Re-evaluate your data sources regularly

- Use tools that make finding reports easy

- Stay ahead of macroeconomic and seasonal trends that could impact sales

11. Incorrect Needs Analysis

People don't always know what they need.

Sometimes, especially in the corporate environment, the person buying the software or setting up procurement solutions may not even be the person who will be using them. In cases like these, buyers will often pick something with tons of features. After all, the more expensive something is, the better it has to be, right? Not always.

Many solutions on the market come with a ton of bloat to try to convince you that their product is somehow worth the extortionary fees they’re trying to charge.

Some red flags include:

- Jargon, and lots of it

- Big numbers you aspire to but may never reach

- Customer support that’s limited to a chatbot

This can lead to a waste of employees’ time as they try to learn about stuff they don’t need, an increase in employees’ frustration as they try to deal with unhelpful AI customer service, and ultimately, a hole in your budget that could have been better allocated if you’d just asked your employees what they actually need.

The solution: Ask your employees what solutions they need. Seriously, it’s as easy as that. And rope them into the process of buying the software.

No one can tell you what the team needs except the team themselves. Listening to your stakeholders, buyers, and contract managers to find solutions that work for them is a recipe for success.

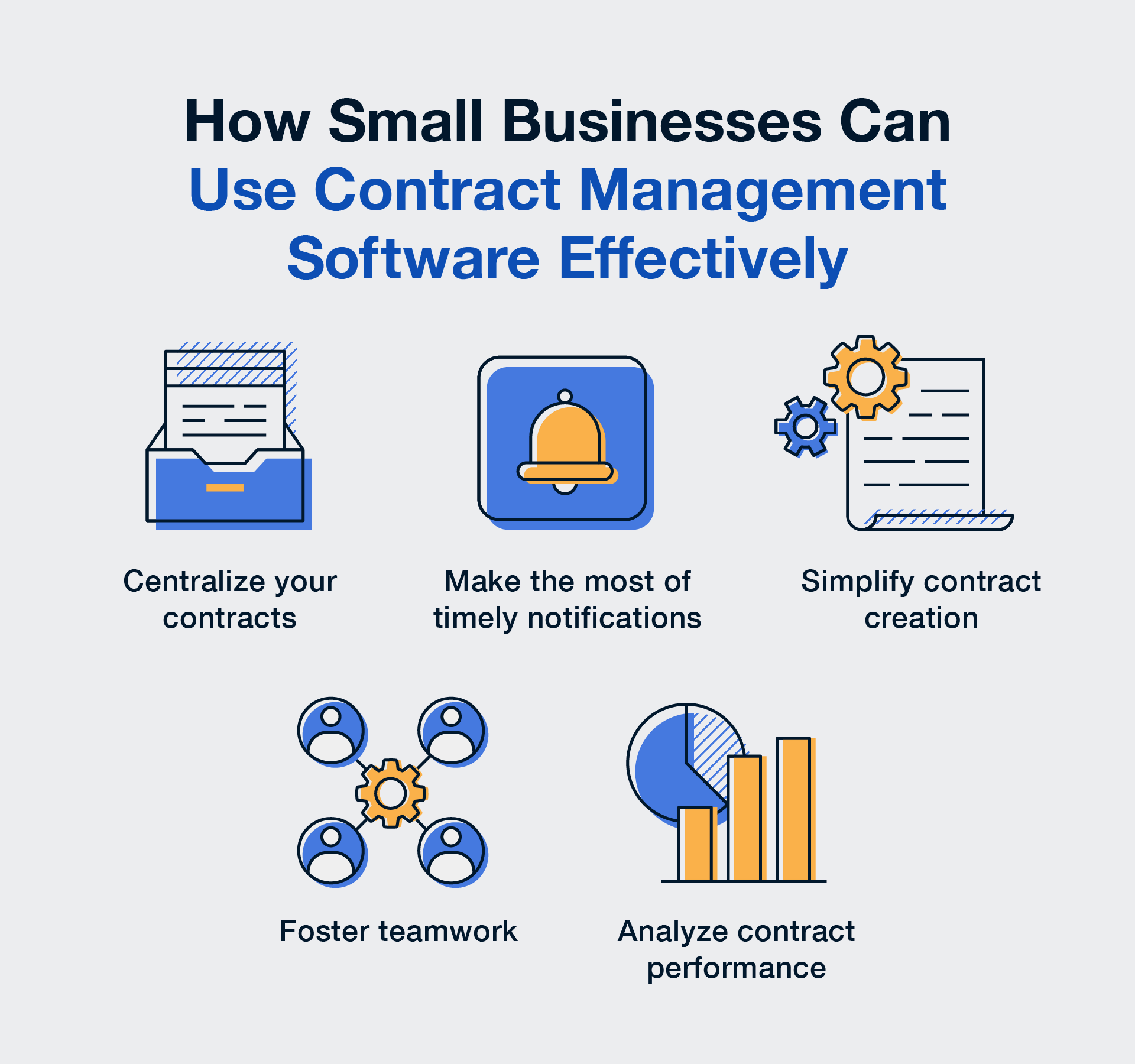

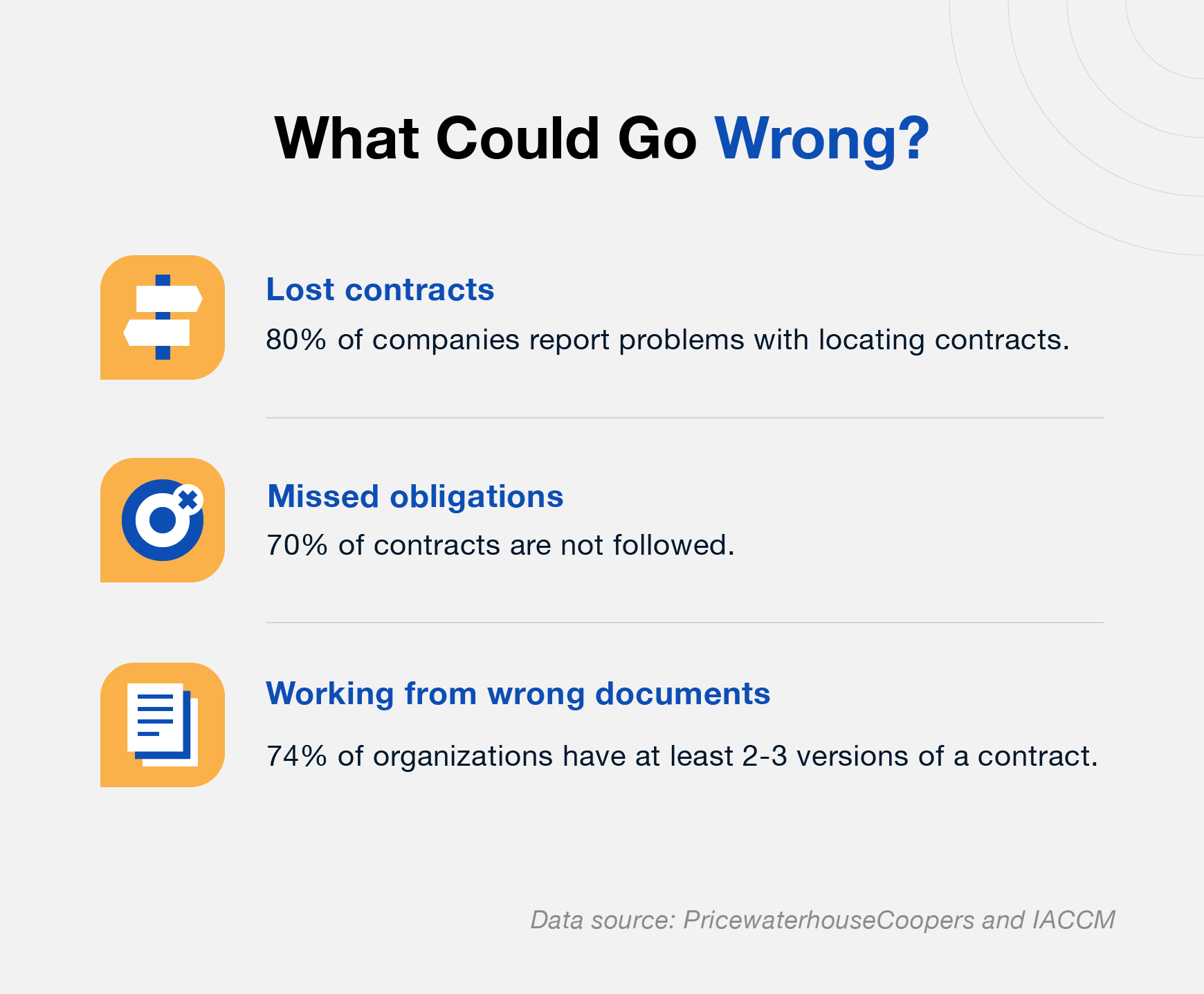

How Contract Management Software Can Help Minimize Procurement Risks

Using contract management software won't protect you from bad driving through the Suez Canal, but it can help you minimize other types of procurement risks.

Here are a few ways you can use contract management software to minimize procurement risks:

- Spot trends and anomalies in the purchasing process to identify and address any potential problems early on.

- Create an audit trail for all purchases and contracts, allowing you to quickly and easily identify where problems might have occurred.

- Develop a feedback loop for both suppliers and management to monitor performance.

- Automate the contract management process, ensuring all data is up to date and accurate.

- Streamline communications with suppliers to make sure everyone is on the same page and agreements are followed.

- Provide automated alerts when contractual conditions change or need to be renewed.

- Simplify the creation of purchase orders and invoices, reducing human errors in data entry as well as improving accuracy.

- Make it easier to compare quotes from different vendors so you can get the best deal quickly and easily.

- Ensure compliance with government regulations on procurement processes.

- Facilitate dispute resolution between vendors, suppliers, distributors, customers, and other stakeholders involved in the process.

Using contract management software, companies can track their contracts from start to finish, easily and efficiently.